Safety-Related Systems | Nuclear Handling Solutions |

Critical Containment Control

Delkia Nuclear Solutions

Delkia delivers a comprehensive package of high-integrity products and solutions for customers operating in demanding and safety-critical industries. Whether you need bespoke engineering design, advanced digital control systems, remote-handling robotics or critical containment control systems. Delkia combines technical expertise, rigorous quality standards and a flexible, end-to-end delivery model - from concept through design, development, build, testing, commissioning and lifelong support.

A UK-based engineering and technology company, Delkia specialises in safety-related systems for nuclear, including process controls, EC&I, glovebox containment control, design, technical consulting and system integration for the most critical applications within the nuclear industry.

We are proud to support the future of engineering by employing apprentices, graduates and veterans. We are also committed to supporting our local community, Net Zero, and are proud to support the Armed Forces Covenant.

Stephen Neale, MD - Delkia Nuclear Solutions

“Whether you require a fully engineered glovebox system, remote handling solutions or a material transfer system, all are delivered through Delkia’s integrated nuclear control and digital architecture - ensuring safety, security, and lifecycle resilience. Delkia provides safe, compliant and innovative solutions tailored to nuclear needs.”

Contact us

Delkia Head Office

Delkia Nexus Centre

Unit 3, Marlborough Way

Haydock

WA11 9FT

Delkia - Cumbria

Sutton House,

Dovenby Hall

Cockermouth

CA13 0PN

Our Products and Solutions

-

![A close-up view of a complex laboratory or industrial processing equipment with various glass bottles, gauges, pipes, valves, and circular metal frames.]()

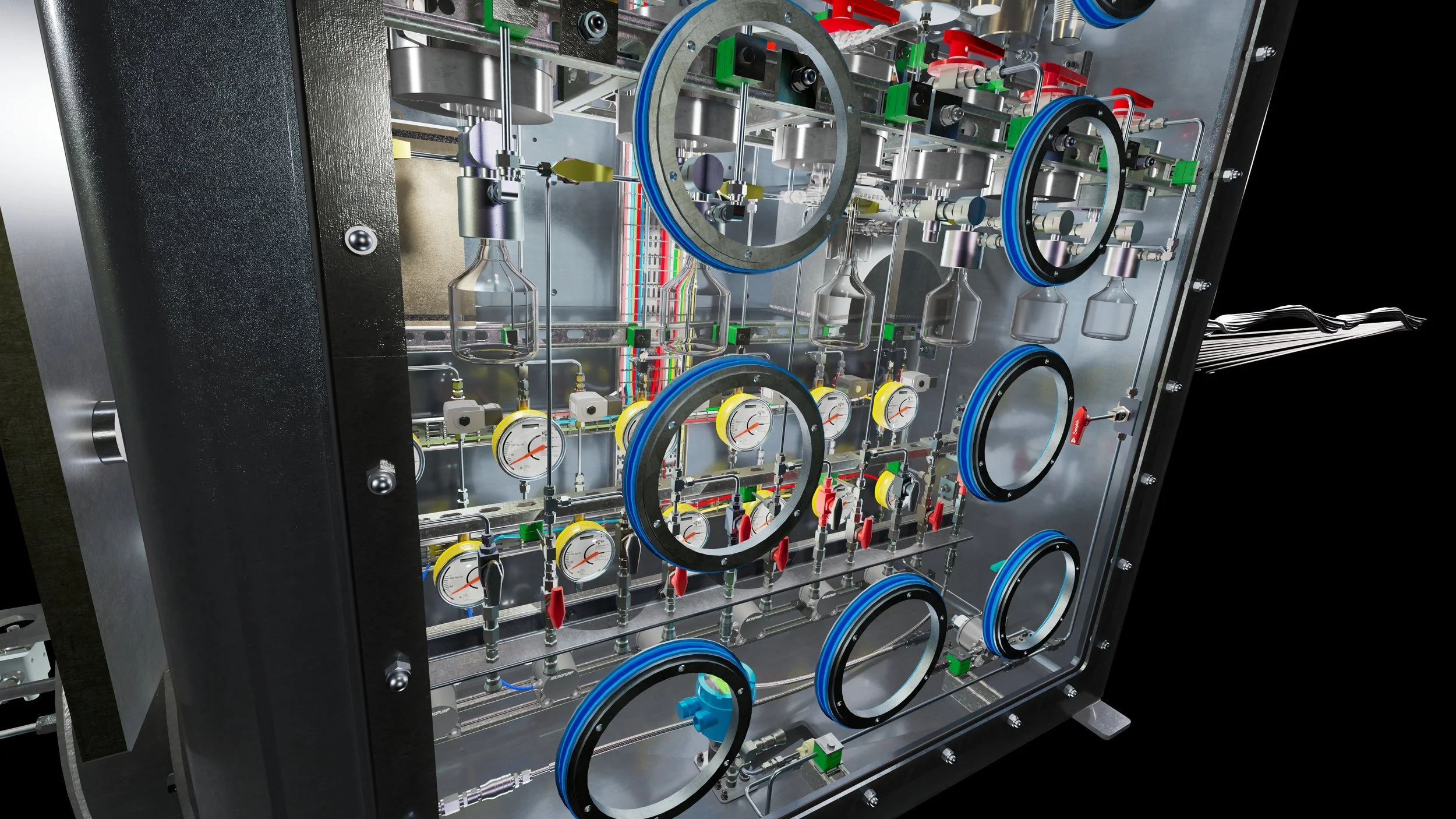

Radiometric and Nucleonic Systems (BEMS and EMS)

Delkia radiometric systems are engineered measurement and monitoring systems used to detect, measure, and monitor radiation in nuclear and other hazardous environments. Their primary purpose is to provide accurate, reliable radiological information that supports safe operation, regulatory compliance, and protection of people, plant, and the environment.

These systems typically incorporate radiation detectors (such as gamma, beta, or neutron detectors), signal processing electronics, and associated instrumentation to measure parameters like radiation level, activity, dose rate, or contamination. Delkia focuses on the engineering, integration, and control of these systems rather than just supplying detectors, ensuring they function correctly within the wider facility.

A key part of Delkia’s offering is the integration of radiometric systems with control and safety systems, including PLCs, alarms, interlocks, and HMI/SCADA interfaces. This allows radiation measurements to be displayed clearly to operators, logged for compliance and traceability, and used automatically to trigger protective actions if predefined limits are exceeded.

Overall, Delkia radiometric systems provide trusted radiological monitoring that underpins safe nuclear operations, supporting activities such as material handling, process control, waste management, and decommissioning while helping to minimise radiation exposure and operational risk.

-

![A person in a control room operating a robotic arm through multiple monitors, supervising an industrial process involving machines and containers in a high-tech environment.]()

Remote Handling Solutions

Delkia delivers robotic and remote-handling solutions for hazardous, radioactive, or inaccessible environments where human entry is unsafe. Our capabilities include robotic manipulators, automated inspection tools, mobile platforms, and bespoke remote-handling systems tailored to operational challenges. These technologies reduce risk, improve precision, and enhance efficiency while meeting the highest safety standards. With expertise in sensing, control, autonomy, and system integration, Delkia provides reliable robotic solutions that extend human capability and protect personnel—ideal for waste sorting, decommissioning, inspection, and hot-cell operations.A major Delkia strength is control and systems integration, which underpins remote handling, PLC-based control systems, HMI and SCADA interfaces for operator control, interlocks and safety logic to prevent unsafe actions, integration with radiometric and nucleonic instrumentation

This ensures remote handling equipment operates safely, reliably, and predictably. Delkia’s remote handling solutions are commonly used for special nuclear material handling, fuel and waste processing, decommissioning and dismantling, maintenance inside radioactive environments, research and laboratory nuclear operations

-

![Industrial machine with robotic arms and containers, likely used for automated manufacturing or testing processes.]()

Special Nuclear Material Transfer Systems

A Delkia Special Nuclear Material (SNM) Transfer System is an engineered, safety-related system used to move special nuclear materials between controlled areas within a nuclear facility. The system ensures that material is transferred without breaking containment, protecting people, plant, and the environment from radiological and contamination risks.

These systems typically combine sealed transfer hardware (such as shielded transfer ports, alpha-tight containers, and airlocks) with remote handling equipment, so materials can be moved and positioned without direct human contact. Delkia integrates these mechanical elements with control, interlock, and monitoring systems that enforce correct transfer sequences and prevent unsafe actions, reducing reliance on operator intervention.

Delkia’s role is to design, develop, build, test, and support the complete transfer solution, ensuring it meets nuclear safety, security, and regulatory requirements. The result is a reliable and compliant method for transferring special nuclear material during operations such as processing, storage, waste handling, or decommissioning while minimising radiation dose and operational risk.

-

![Industrial safety control panel with warning signs, touchscreen display, and electrical components in a laboratory or industrial setting.]()

Safety Mechanism Systems

Delkia safety mechanism systems are engineered, safety-related systems designed to prevent, control, or mitigate hazardous events in high-risk environments, particularly within the nuclear sector. Their purpose is to ensure that plant operations remain within safe limits and that people, equipment, and the environment are protected if abnormal or fault conditions occur.These systems typically include mechanical, electrical, and software-based safety mechanisms such as interlocks, permissives, failsafe devices, emergency shutdown functions, and protective barriers. Delkia designs these mechanisms so that unsafe actions are either physically impossible or automatically prevented, reducing reliance on human intervention.

A key element of Delkia’s safety mechanism systems is their safety-critical control architecture, often based on PLCs with defined safety functions, alarms, and status monitoring. These systems enforce correct operating sequences, detect faults or abnormal conditions, and trigger protective responses such as isolation, shutdown, or containment. All safety mechanisms are developed in line with nuclear safety principles, functional safety standards, and regulatory expectations.

Overall, Delkia’s safety mechanism systems provide assured, demonstrable safety by combining robust engineering, verified control logic, and lifecycle support, helping nuclear facilities operate safely during normal operation, maintenance, and decommissioning.

-

![Laboratory workers in blue protective suits and masks working with high-tech equipment in a sterile, metallic environment.]()

Glovebox Control and Containment Systems

Delkia glovebox control and containment systems are integrated engineering solutions that allow hazardous or radioactive materials to be handled safely inside sealed enclosures while maintaining strict containment and operational control. They are commonly used in nuclear facilities where direct human contact with materials would present unacceptable radiological, contamination, or safety risks.The containment system consists of the glovebox structure itself, including sealed panels, glove ports, viewing windows, transfer ports, and ventilation interfaces, all designed to prevent the release of radioactive or toxic substances. Delkia ensures the glovebox maintains the required containment integrity, pressure regime, and interface compatibility with surrounding plant systems.

The control system manages how the glovebox operates and interacts with operators and other equipment. Delkia designs and integrates PLC-based control systems, safety interlocks, alarms, and HMI interfaces that control doors, transfer ports, manipulators, and environmental conditions such as pressure and airflow. These controls prevent unsafe states, enforce correct operating sequences, and support compliance with nuclear safety requirements.

Together, Delkia’s glovebox control and containment systems provide a safe, reliable, and compliant working environment that enables precise material handling while minimising operator dose and reducing the risk of contamination or containment failure.

-

![Person holding a tablet with a control system dashboard in a robotic manufacturing environment with robotic arms.]()

Engineering & Digital Solutions

Delkia engineering digital systems are integrated digital and software-based solutions that support the design, control, monitoring, and assurance of complex engineering systems, particularly in safety-critical and highly regulated sectors such as nuclear.These systems typically include digital control platforms, software applications, data acquisition, and visualisation tools that allow plant and equipment to be operated, monitored, and maintained in a controlled and traceable way. Delkia applies strong systems engineering principles to ensure digital solutions are robust, secure, and suitable for use in environments where reliability and safety are essential.

A key aspect of Delkia’s engineering digital systems is the integration of digital tools with physical plant and safety systems, such as PLCs, instrumentation, radiometric systems, and remote handling equipment. This enables real-time monitoring, automated control, alarm management, and data logging, giving operators and engineers clear insight into system status and performance.

Overall, Delkia’s engineering digital systems help organisations improve operational safety, efficiency, and compliance by providing dependable digital control, information management, and decision-support capabilities across the lifecycle of complex engineering systems.

Case Studies

-

![Industrial cleanroom with stainless steel laboratory equipment, including control panels and a fume hood with glove ports.]()

Delivering High-Integrity Glovebox Control Systems

Cyclife Aquila Nuclear required nine high-integrity gloveboxes, complete with ports and transfer ports, to support advanced processing technology and aqueous recycling as part of the UK’s Nuclear Innovation Programme. The solution needed to meet stringent safety standards, integrate complex control systems, and be delivered within a demanding schedule for a multimillion-pound project.

Delkia provided a full turnkey service, including concept, preliminary and detailed design, procurement, manufacture, and testing. Built at Delkia’s dedicated facilities, the gloveboxes were engineered for reliability and compliance. The scope also included factory and customer acceptance testing, commissioning, and handover. By combining engineering design, systems integration, and technical consultancy, Delkia delivered a solution that enhances nuclear safety and efficiency while supporting the UK’s clean energy objectives. -

![Group of people wearing yellow high-visibility vests inspecting large electrical or infrastructure equipment inside a facility.]()

Programme and Project Partner for Sellafield

“Delkia demonstrated its breadth of expertise, facilities, and personnel to deliver this critical package for SRP,” said Richard Etheridge, Senior Project Manager for SRP MEICA, Morgan Sindall.

Delkia secured one of the first major packages of work from the multi-billion-pound Programme and Project Partners framework for Sellafield — specifically for the Sellafield Product and Residue Store Retreatment Plant (SRP).

The package included the design, build, and testing of an ancillary instrumentation control system for SRP gloveboxes.

Key deliverables included: concept and detailed design; early procurement and supply chain management; safety-related systems and substantiation supporting the safety case; liaison with IC and process authority; full integration, works testing, and delivery to the client.

“Their demonstration of technology advances and processes for this design and build project was to very high standards,” said Marc Pantoni, Package Lead.

-

![Building evacuation control system monitor displaying alarm status with red and yellow alert messages, sensor readings, and system diagnostics, in a control room environment.]()

Reliable, low-cost radiometric surveillance equipment

Delkia developed a radiometric surveillance system (RSS) in partnership with alarm manufacturer Omniflex.

Using Omniflex Teleterm M3E hardware, Delkia developed an RSS solution that allows for trend analysis and real-time data monitoring. The system can both initiate an evacuation and lock down the client’s facility by using audible and visual warning units that are individually rated to SIL-2 level. This is all at an affordable cost—removing a common barrier to small-scale RSS implementation.

“We combined our experience in software development and systems integration with Omniflex’s extensive knowledge of interfacing with all types of radiation monitors and technical support. In an industry where safety is paramount, partnerships like these create technology that ultimately protects assets, people, and the environment from preventable radiation exposure. Long may it continue.” —Kurt Canfield, CEO.

-

![Robotic arms and machinery in an industrial setting, with four men in business attire discussing near a control panel.]()

Robotics

Delkia recently partnered with robotics pioneer Kawasaki to develop, integrate, and test software controlling a robotic arm for nuclear waste categorisation. Our team handled software development, integration, and testing to help control movements and safety-critical functions, ensuring precision and reliability. Build-to-print contracts like this combine Delkia’s expertise in software and systems integration with Kawasaki’s technical input and engineering support.

“Delkia maintains a high standard of technical consultancy, honed through years of industry experience. This collaboration has already delivered a pre-programmed robot with excellent control and functionality,” said Stuart Cheyne, UK Marketing and Sales Manager at Kawasaki Robotics. The final model will sort and manage different categories of nuclear waste, making processes safer and more cost-effective than current industry methods.

Delkia has expanded into Sutton House at Dovenby Hall Estate, Cockermouth, following the opening of its 18,000 sq. ft engineering production centre in Haydock. The 5,960 sq. ft site offers offices, training and collaboration space. Malcolm Wilson OBE welcomed Delkia, handing keys to MD Stephen Neale and CFO Amy Bryant.

A new engineering production centre has opened in Haydock, near St Helens, as specialist engineering and technology company Delkia expands its operations into Merseyside. The 18,000 sq ft manufacturing facility was officially opened by David Baines, Labour MP for St Helens North, marking a major step for the British company.

Delkia won the BECBC Growing Business of the Year Award in 2024. This year, we’re giving back to the West Cumbria business community by sponsoring the Empowering the Future Generation Award 2025 - a category that reflects our values and commitment to investing in talent through apprenticeships and our Graduate Scheme.

Delkia, a leading UK-based specialist systems integrator for safety-related and mission-critical systems, will showcase its advanced engineering capabilities at DSEI 2025, the world’s premier defence and security exhibition at ExCeL London from 9–12 September. The team will highlight cutting-edge expertise in systems integration, digital engineering, and technical consultancy.

Whitehaven Sea Cadets have received a £600 donation from specialist engineering and technology company Delkia to support refurbishment of their new unit. The cadets have been in temporary accommodation since storms damaged their barracks in 2013. Essential renovations include a fire alarm system, electrical rewire, and a new roof.

Nine primary schools in Cumbria have received a share of £2,000, donated to help foster a love of STEM subjects in young learners, courtesy of specialist engineering and technology company Delkia. The company, which operates in the aerospace, nuclear and maritime sectors, chose to sponsor STEM initiatives as part of…

Delkia is proud to announce that Kurt Canfield, CEO of Delkia, has been appointed to the Board of Trustees at Whitehaven Community Trust (WCT), a vital charity dedicated to supporting vulnerable individuals and families across West Cumbria. WCT provides essential support in areas such as homelessness, domestic violence, mental health...

We are happy to share the successful completion of the recent SyntheSys Data Link Manager / Interface Control Officer (DLM/ICO) course, hosted by the Swedish Naval Warfare Centre in Karlskrona, Sweden, from 11–23 May 2025. The DLM/ICO role is crucial to the Tactical Data Link (TDL) interface, managing both planning and execution functions.

A new engineering production facility is set to open in May and create around 20 new jobs in Haydock, St Helens, as specialist engineering and technology company Delkia expands its operations into Merseyside. Delkia, which specialises in safety-related and mission-critical systems for the defence and nuclear sectors, is expanding its…

We're proud to announce a significant milestone for Synthesys Defence Systems (SDS) – the successful delivery of our first ever Operational Introduction course. Held from 1st to 3rd April, 2025, at Hotel Norden in Haderslev, Denmark, the course was delivered to delegates from FMV, Sweden.

Applications are now open for an ambitious graduate scheme, designed to inspire and mentor the UK’s next generation of leading engineers.

Specialist engineering and technology company Delkia have seen rapid growth in recent years with a large volume of contract wins across all sectors and a host of new team members.

Our Customers include: